Crusher Buckets for Sale at Van-Ed Equipment

Whether you’re involved in construction, demolition, or recycling, crusher buckets are essential in transforming large materials into manageable pieces. These innovative attachments bring power, versatility, and convenience to any worksite, facilitating more efficient and sustainable operations. At Van-Ed Equipment, we’re committed to enhancing your productivity. Serving the Lower Mainland, Fraser Valley, BC, and Western Canada, we offer top-grade crushing buckets from industry-leading brands. Choose Van-Ed for crushing solutions that redefine performance and durability.

New Crusher Buckets

Carrier: 6.5 to 10 tonnes

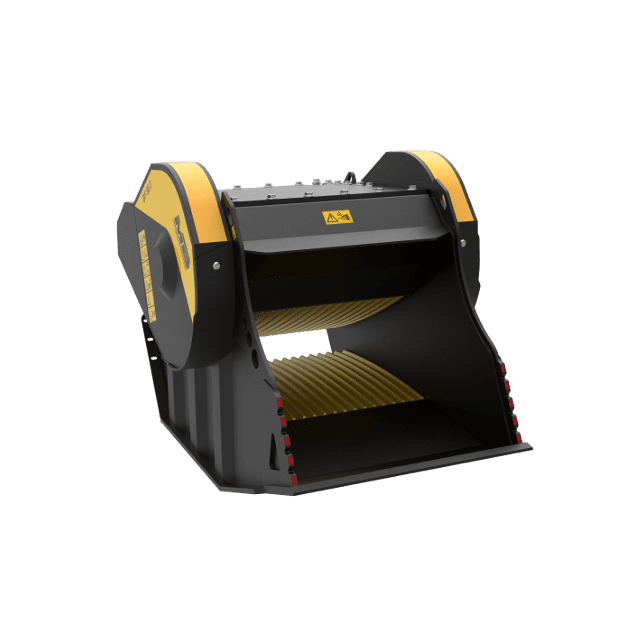

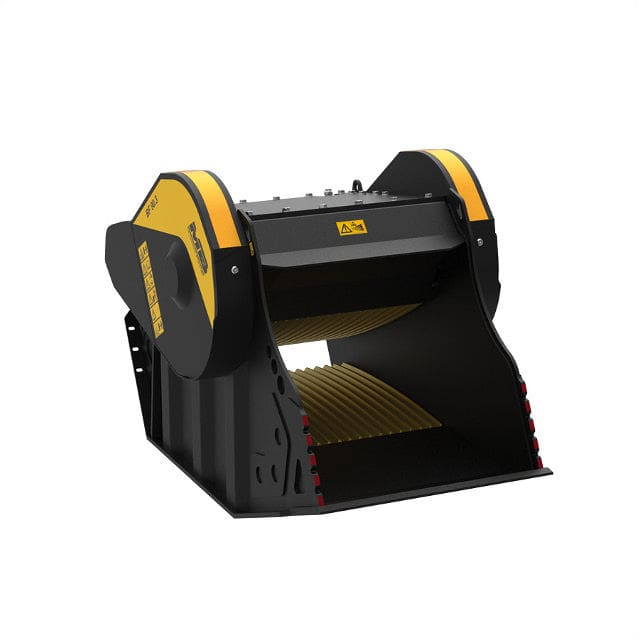

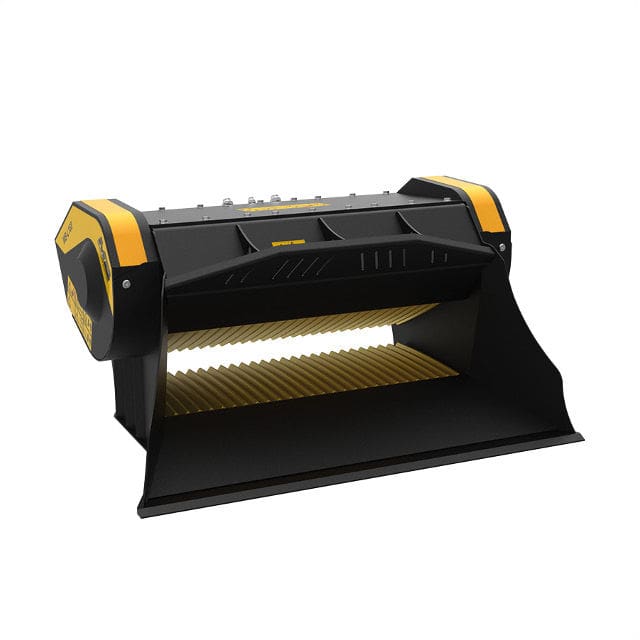

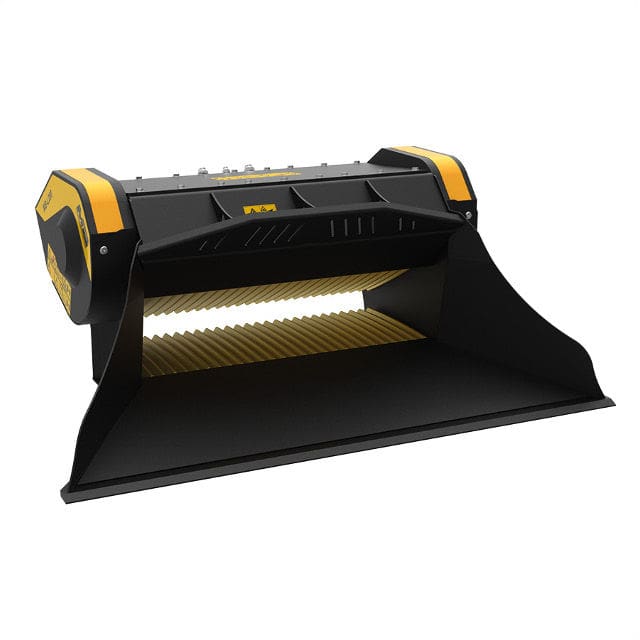

MB Crusher MB-C50 S4

Carrier: 10 to 18 tonnes

MB Crusher BF60.1 S4

Carrier: 16 to 25 tonnes

MB Crusher BF70.2 S4

Carrier: 18.5 to 29 tonnes

MB Crusher BF80.3 S4

Carrier: 21 to 32 tonnes

MB Crusher BF90.3 S4

Carrier: 30 to 45 tonnes

MB Crusher BF120.4 S4

Carrier: 43 to 80 tonnes

MB Crusher BF135.8

Carrier: 70 to 100 tonnes

MB Crusher BF150.10

Carrier: 7.5 to 12 tonnes

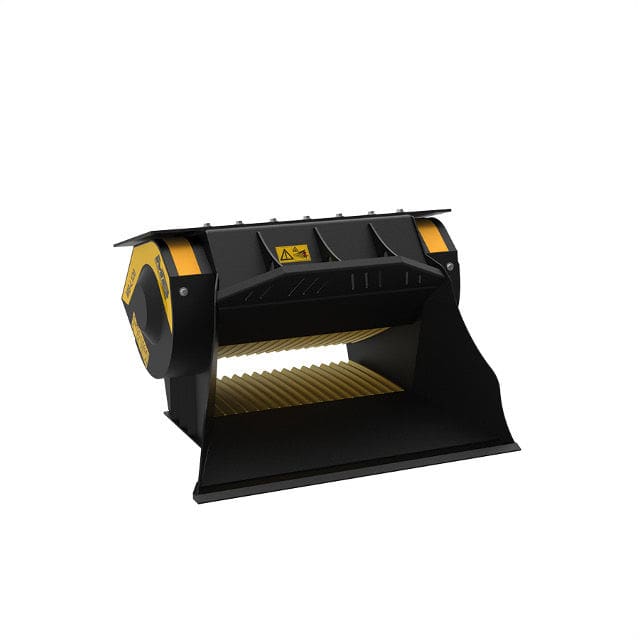

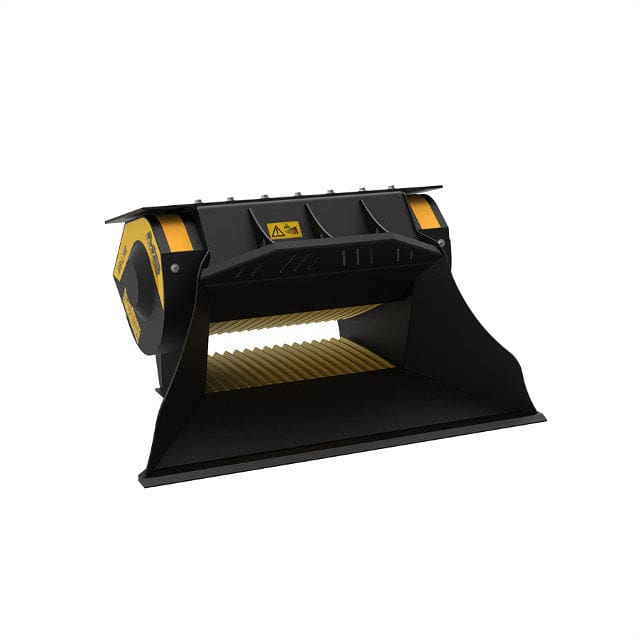

MB Crusher MB-L120 S2

Carrier: 7.5 to 13 tonnes

MB Crusher MB-L140 S2

Carrier: 11 to 16 tonnes

MB Crusher MB-L160 S2

Carrier: 12 to 17 tonnes

MB Crusher MB-L200 S2

Resources About Crusher Buckets

Videos

Specifications

| MB Crusher | ||||

| Model | Weight (Ton) | Load Capacity (M3) | Pressure | Oil Flow |

| MB-C50 S4 | 0,75 Ton | 0,15 | > 200 bar | >90 <130 l/min. |

| BF60.1 S4 | 1,65 Ton | 0,55 | > 220 bar | >120 <180 l/min. |

| BF70.2 S4 | 2,30 Ton | 0,65 | > 220 bar | >150 <200 l/min. |

| BF80.3 S4 | 3 Ton | 0,70 | > 220 bar | >150 >220 l/min. |

| BF90.3 S4 | 3,50 Ton | 0,90 | > 220 bar | >180 <240 l/min. |

| BF120.4 S4 | 4,80 Ton | 0,19 | > 220 bar | >190 <260 l/min. |

| BF135.8 | 7,50 Ton | 1,60 | > 230 bar | >320 <380 l/min. |

| BF150.10 | 10,50 Ton | 2,30 | > 230 bar | >380 <430 l/min. |

| L120 S2 | 0,95 Ton | 0,19 | > 200 bar | 95 l/min. |

| L140 S2 | 0,98 Ton | 0,2 | > 200 bar | 98 l/min. |

| L160 S2 | 1,45 Ton | 0,35 | > 200 bar | 110 l/min. |

| L200 S2 | 1,50 Ton | 0,43 | > 200 bar | 120 l/min. |

FAQ - Frequently Asked Questions

Lifespan varies based on usage and maintenance but typically ranges from 5 to 10 years with proper care and regular servicing.

A crusher bucket works by using hydraulic power from the excavator to which it’s attached. It crushes materials through the movement of its jaws, turning large pieces of debris into smaller, manageable aggregates ready for use or recycling on-site.

The crusher buckets can process feed sizes ranging from small pieces to larger chunks, accommodating various material types and project requirements. The wide mouth opening ensures high throughput and efficient material handling.

Feed sizes also depend on the model and the type of carrier machine (excavators, backhoes, loaders, skid steers) they are mounted on.

Here are some generalized feed size specifications:

Small Crusher Buckets

Mouth width: 590 mm to 610 mm

Suitable for 6.5 to 18-ton excavators and backhoe loaders.

Ideal for smaller job sites and compact applications.

Medium Crusher Buckets

Mouth width: 750 mm to 910 mm

Suitable for 16 to 32-ton excavators.

Versatile for medium-sized construction sites and urban areas.

Large Crusher Buckets

Mouth width: 1205 mm to 1450 mm

Suitable for 30 to 100-ton excavators.

Best for large-scale construction projects, quarries, and mining sites.

The output range of crusher buckets varies depending on the model and the type of material being processed. Generally, crusher buckets can achieve the following output ranges:

Small Crusher Buckets:

Output: 4 to 13 m³/h (depending on material size)

Medium Crusher Buckets:

Output: 9 to 27 m³/h (depending on material size)

Large Crusher Buckets:

Output: 15 to 95 m³/h (depending on material size)

These ranges can vary based on the material’s density and toughness, as well as the specific model of the crusher bucket.

Crusher buckets are versatile attachments used in a variety of applications, including:

Demolition: Crushing and recycling concrete, bricks, and other construction materials directly on-site.

Excavation: Breaking down excavated soil, rocks, and stones for easier handling and transport.

Road Construction: Processing asphalt and other road materials for reuse in new road projects.

Quarries and Mines: Crushing rocks and minerals for aggregate production.

Urban Construction Sites: Managing waste and recycling materials in confined spaces.

Landscaping and Agricultural Areas: Processing organic materials like foliage and soil.

Pipeline and Trench Work: Crushing materials for backfilling and construction of pipelines and trenches.

Foundries: Handling slag, casting mold waste, and other foundry by-products.

Crusher buckets help reduce waste, improve efficiency, and lower project costs by enabling on-site material processing.

Call Van-Ed

Call Van-Ed