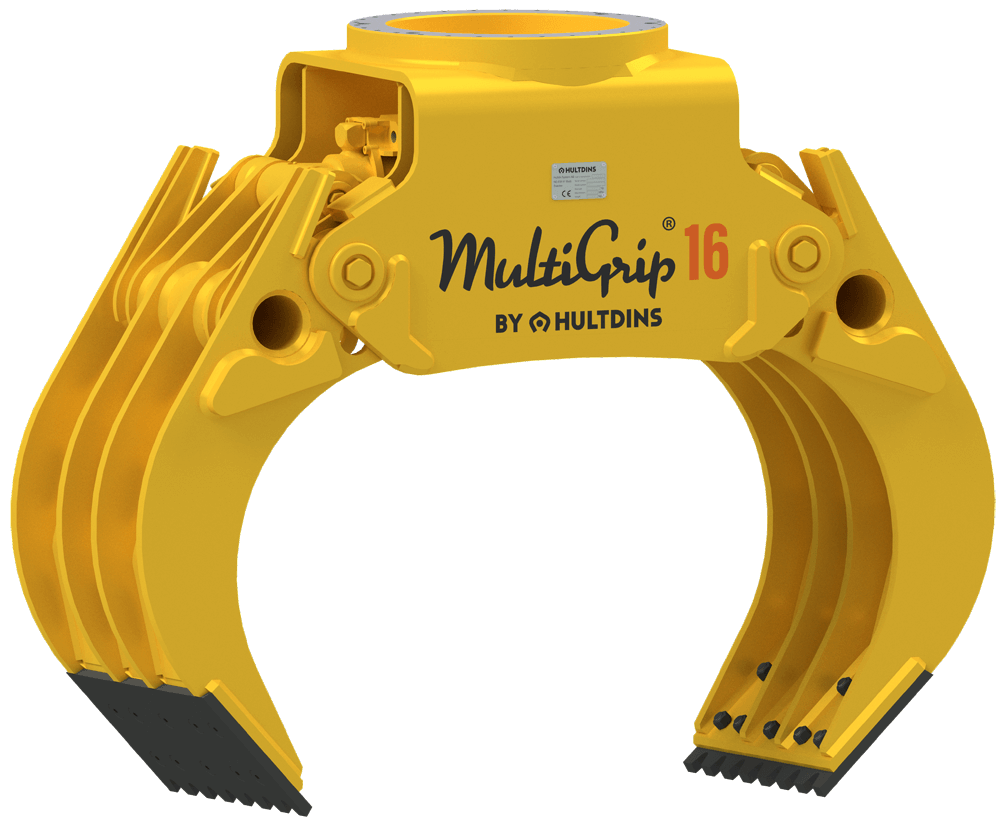

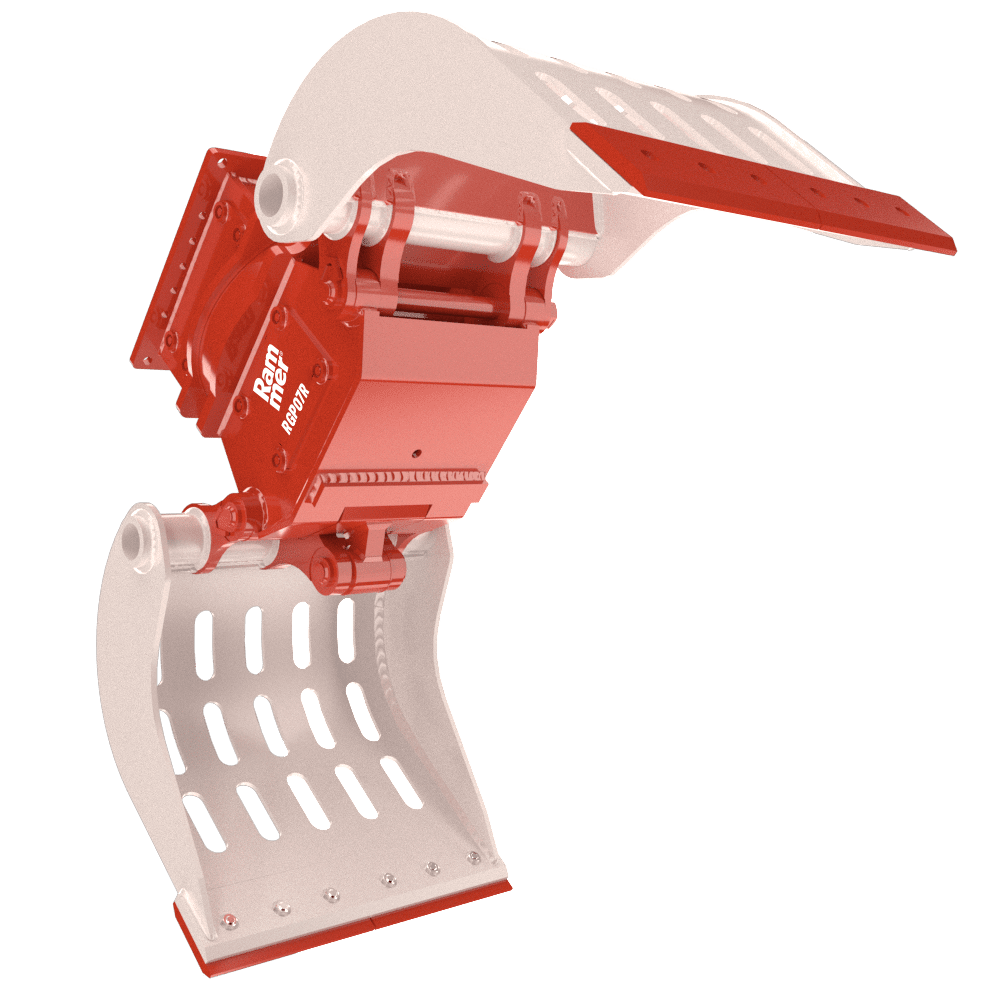

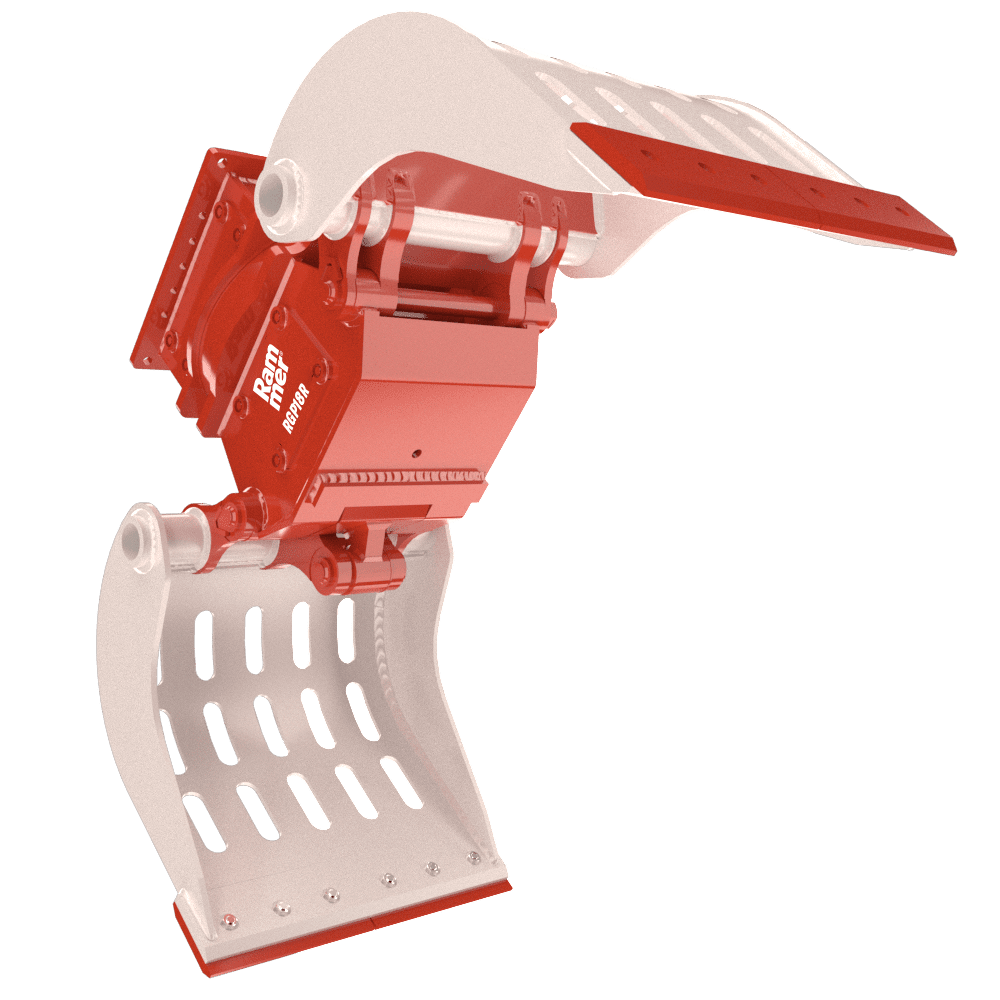

AN EVEN BETTER EXPERIENCE

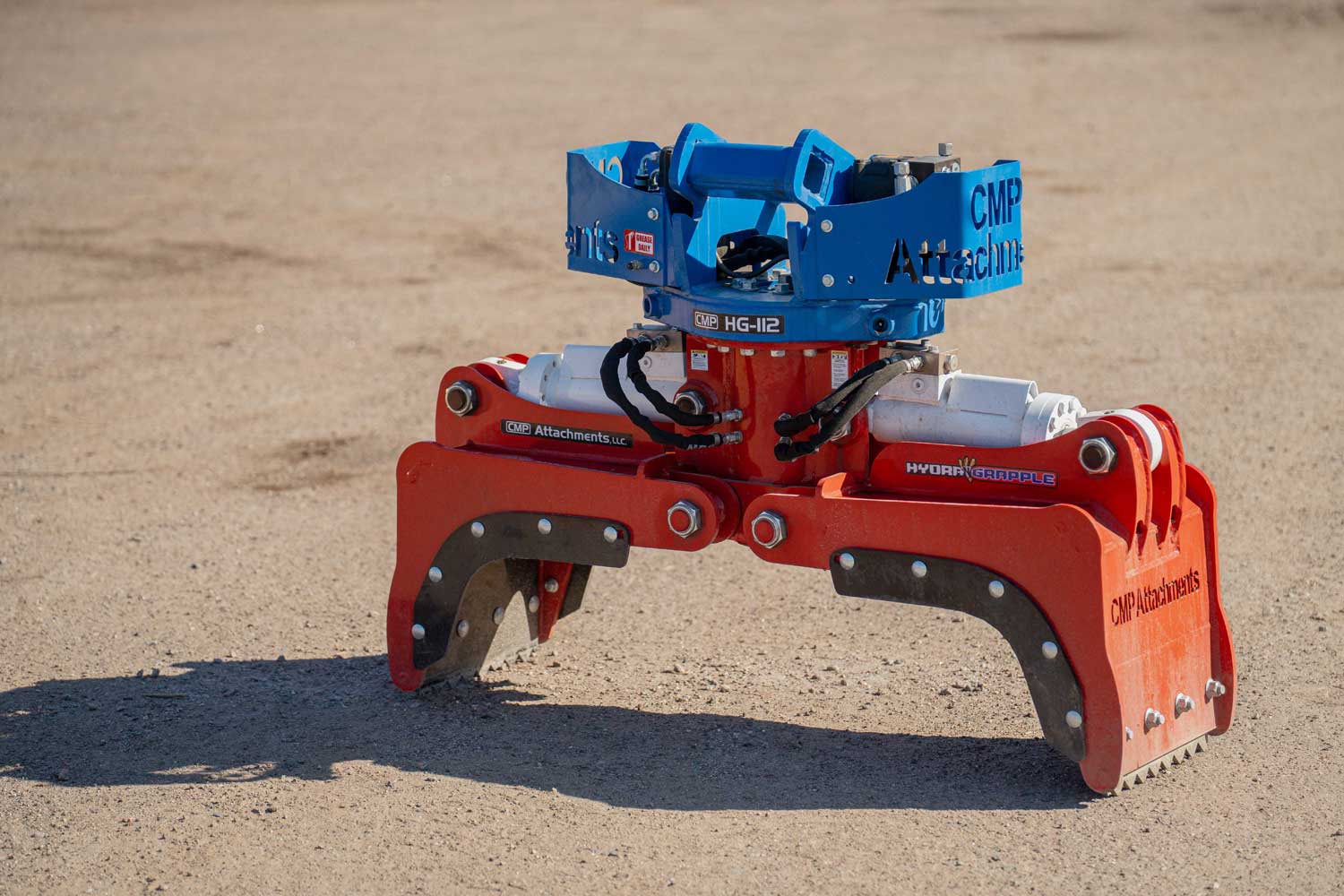

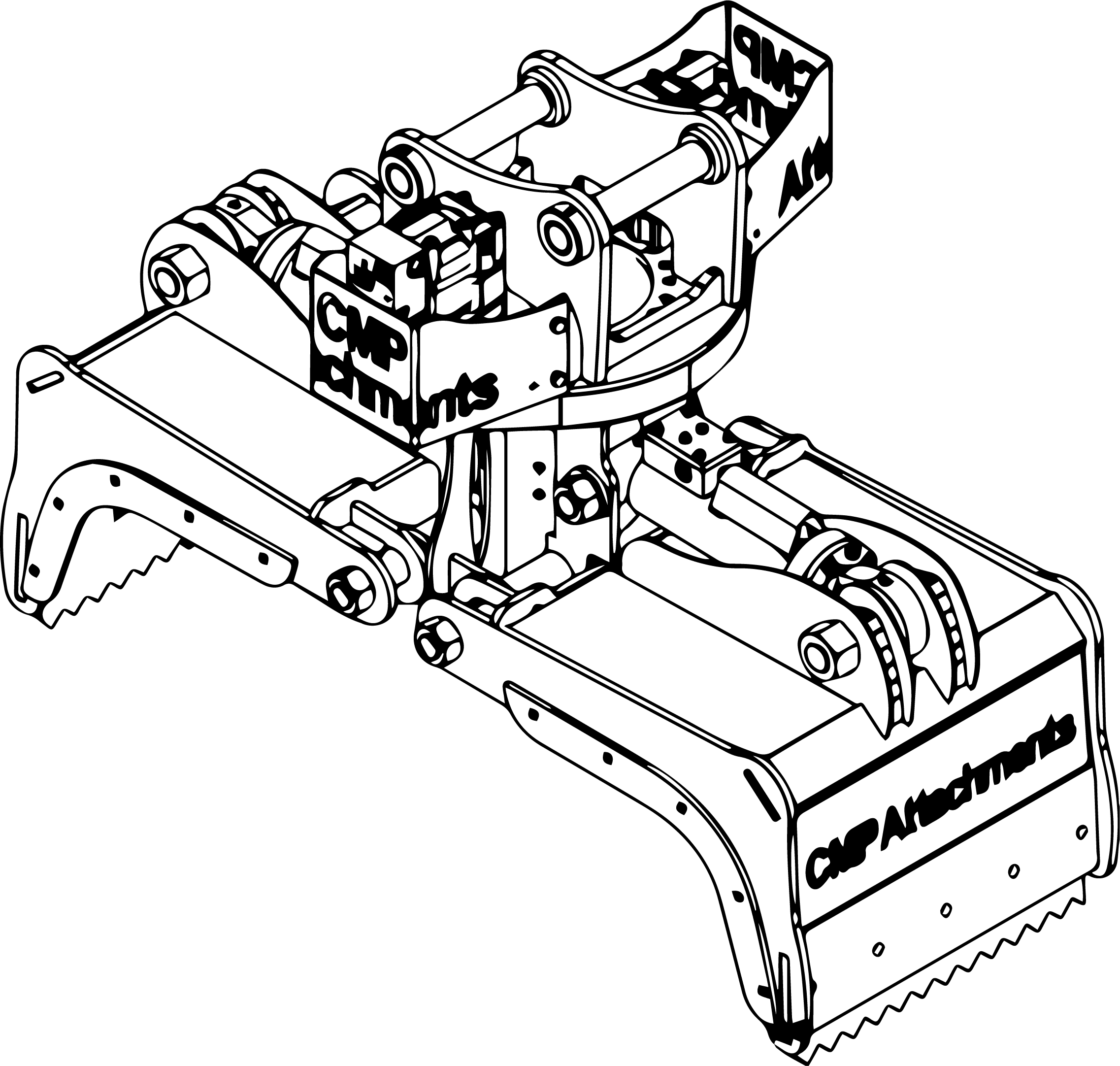

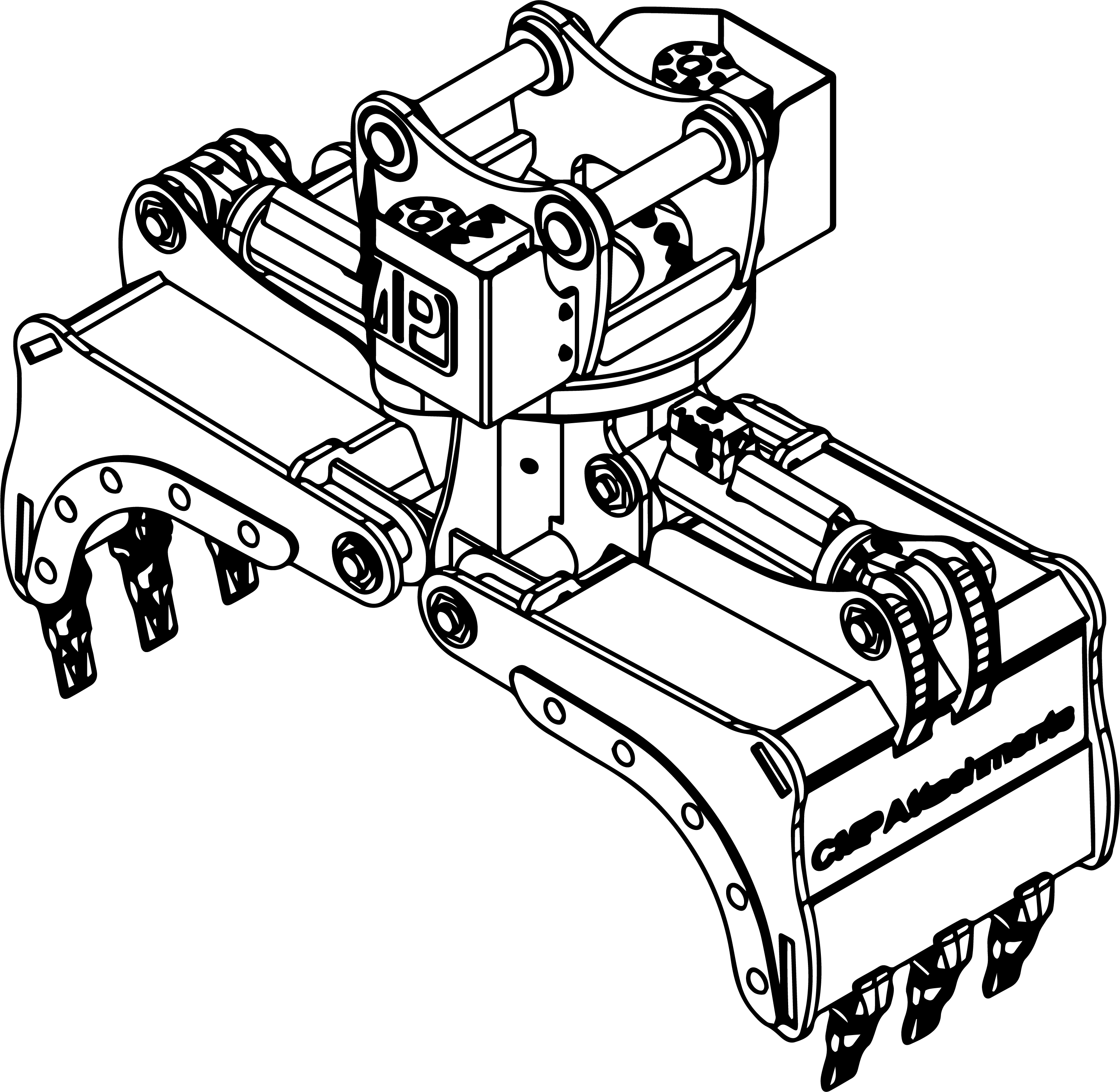

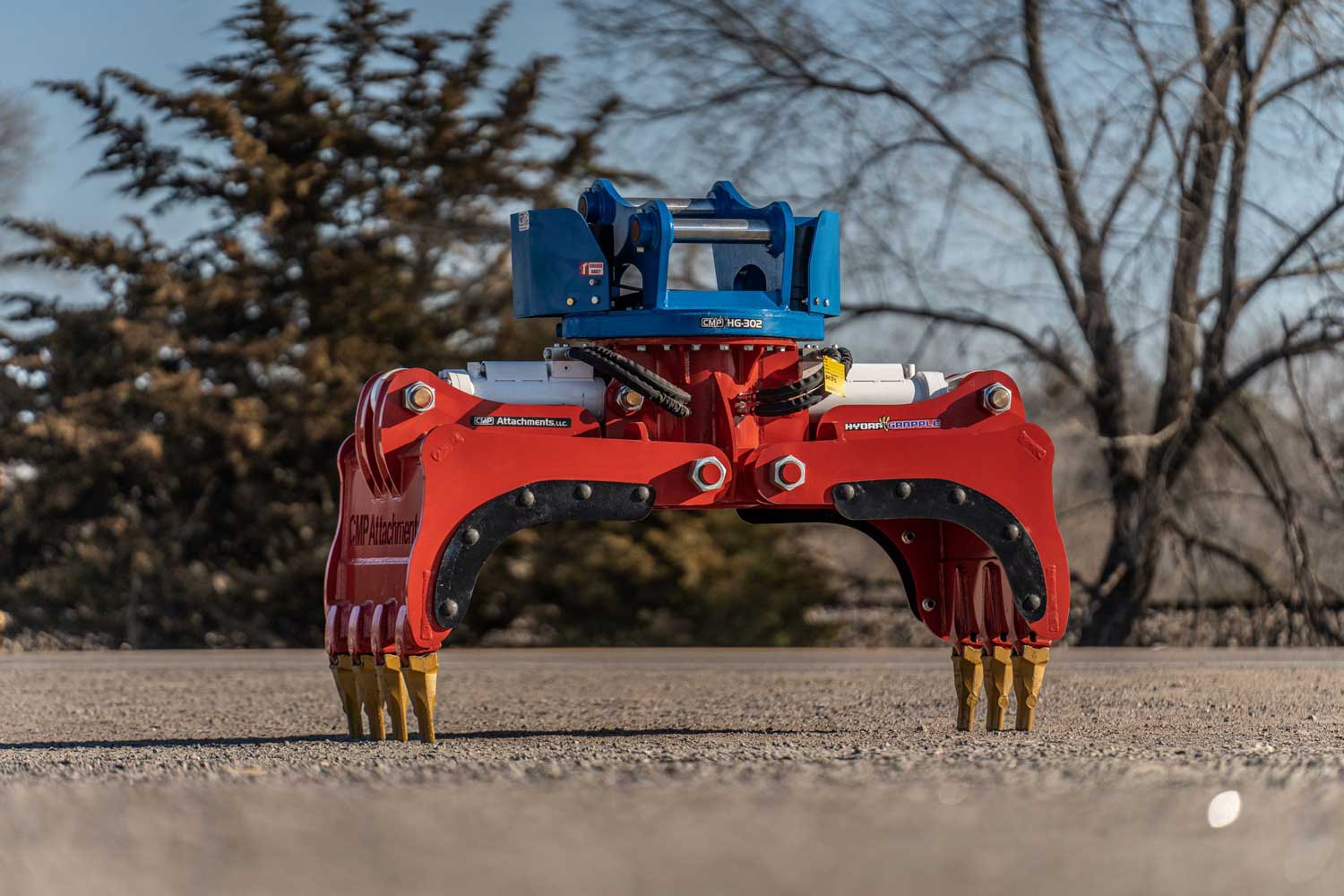

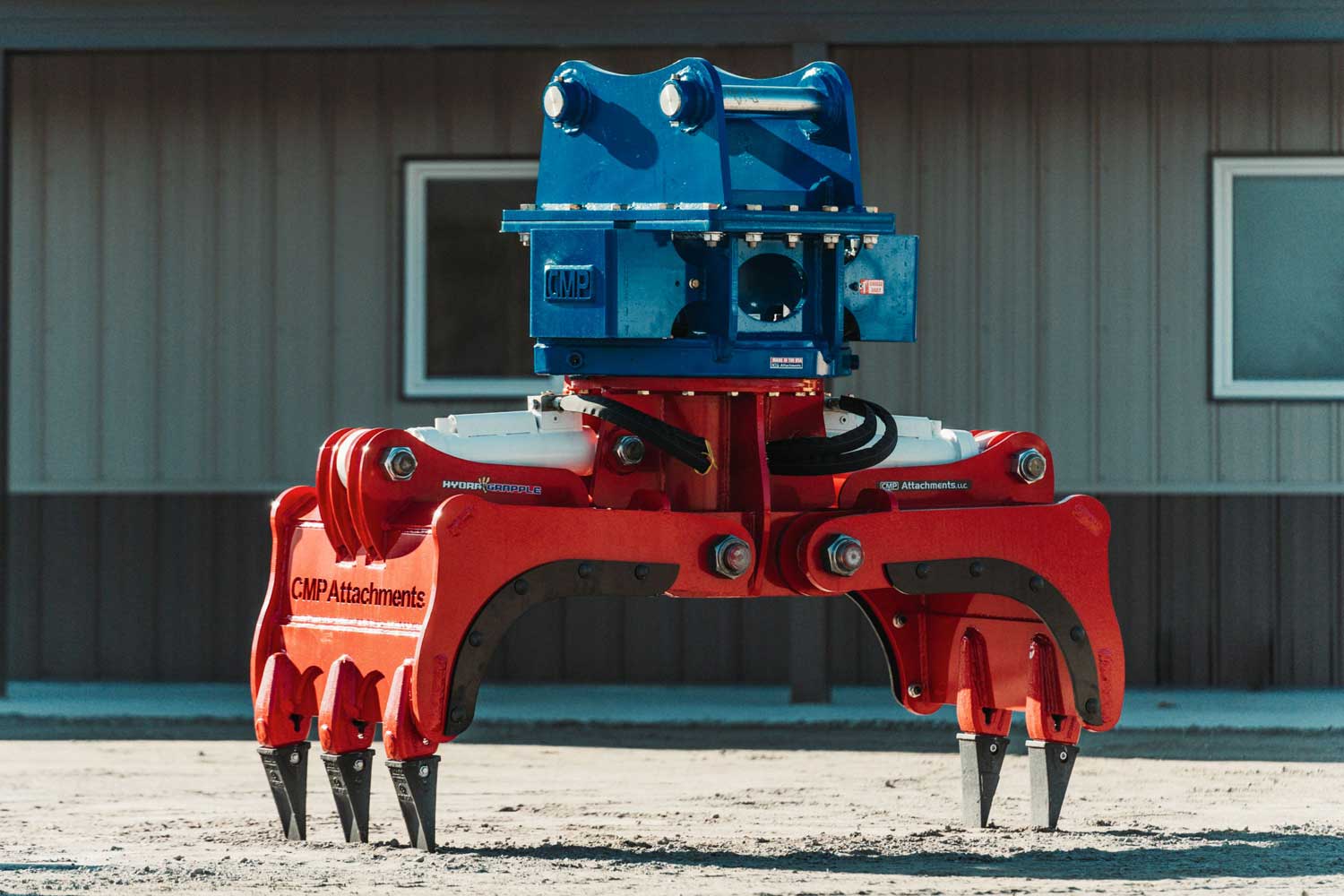

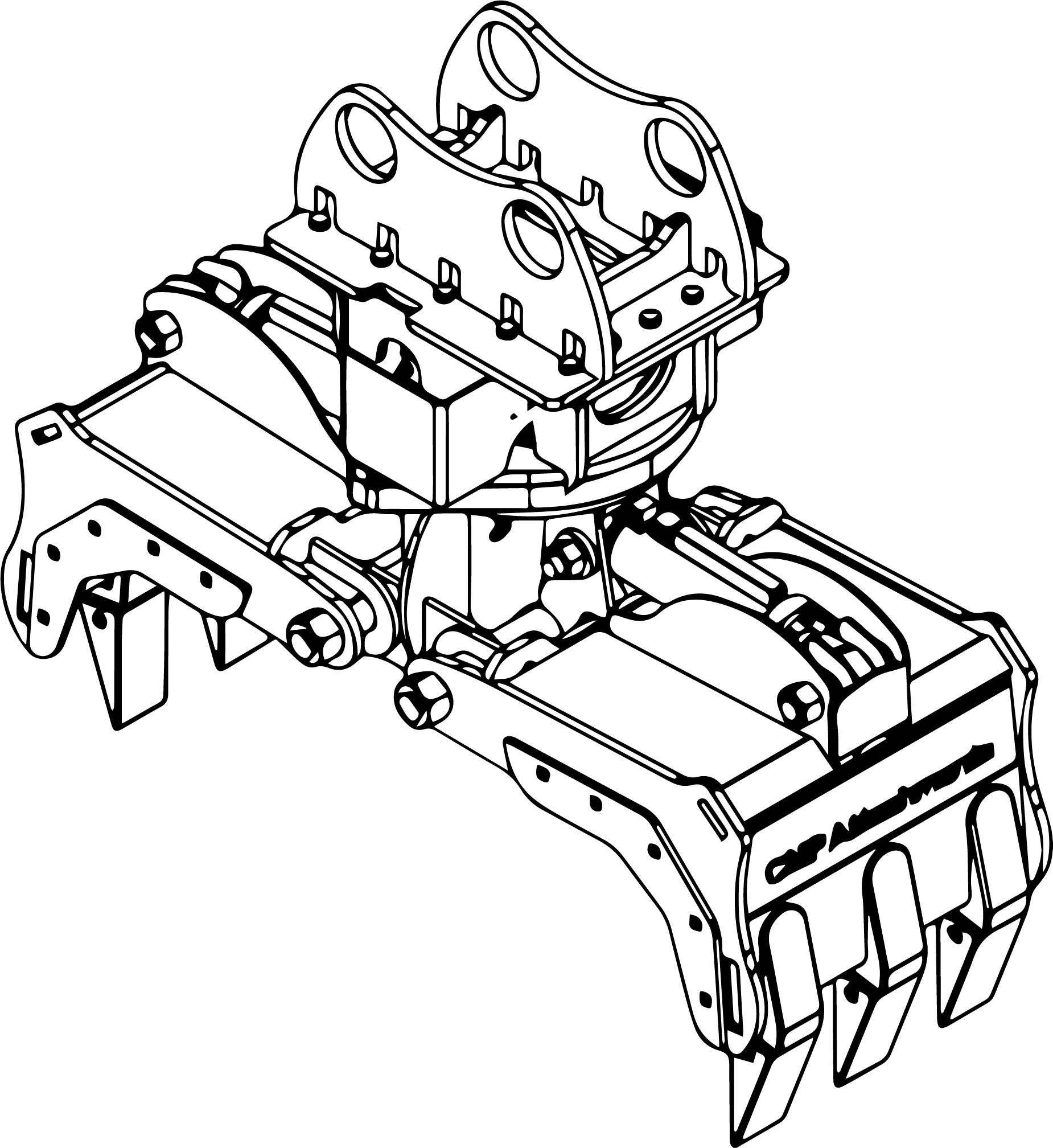

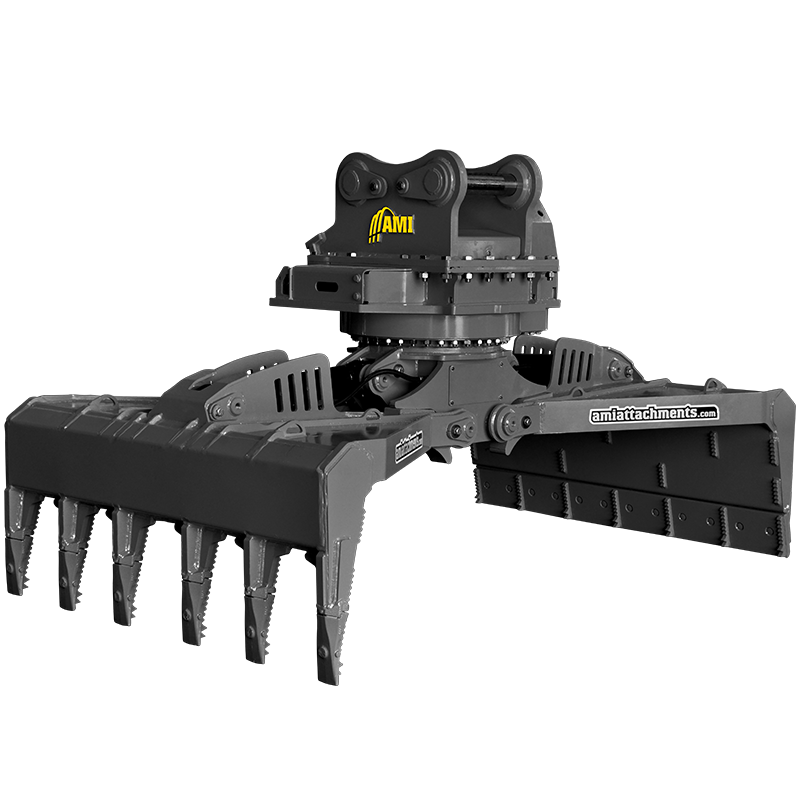

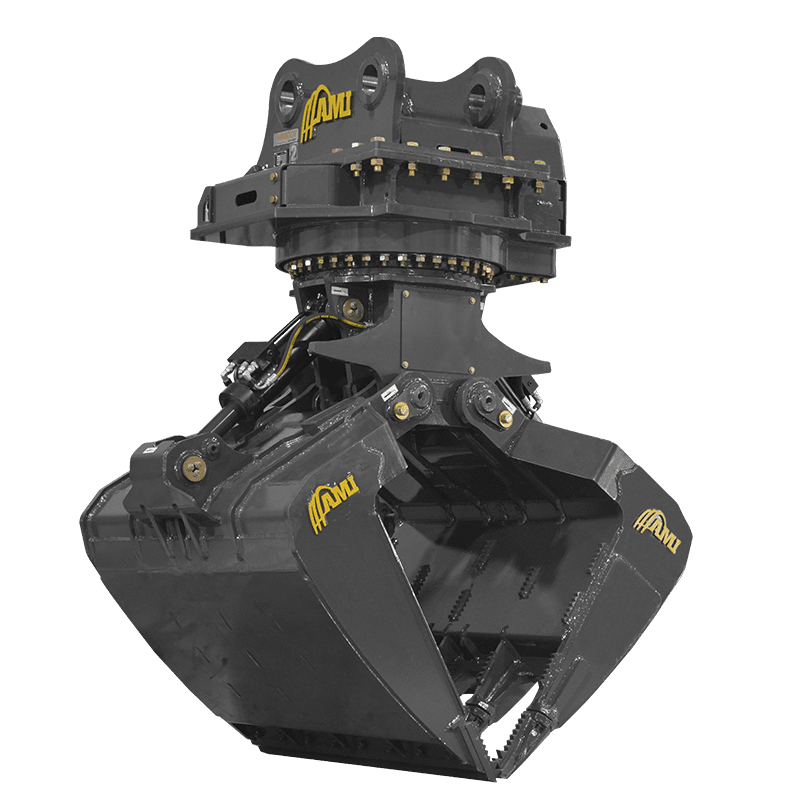

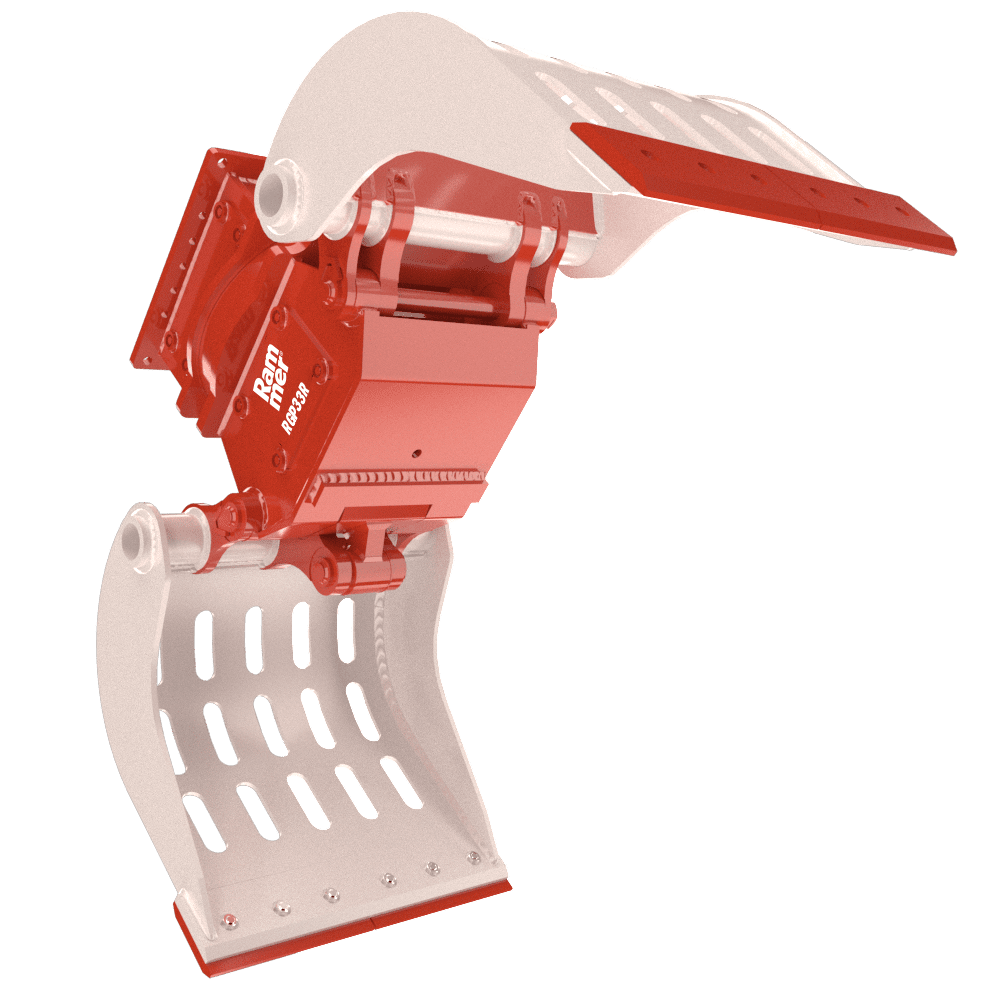

Even though the SuperGrip series includes the world’s most widely used log grapples, we’ve developed the SuperGrip II. The feeling is the same, but with the SuperGrip II we’ve tried to make the most of everything we’ve learned from the SuperGrip. For instance, as far as possible we wanted to avoid welding the frame. A weld is always a possible point of failure. So the frame of the SuperGrip II is made from just four plates that have been laser cut, bent, and welded together in the optimal manner. To reinforce the rotator mount, the SuperGrip II std uses a sturdy Hardox plate as a spacer.

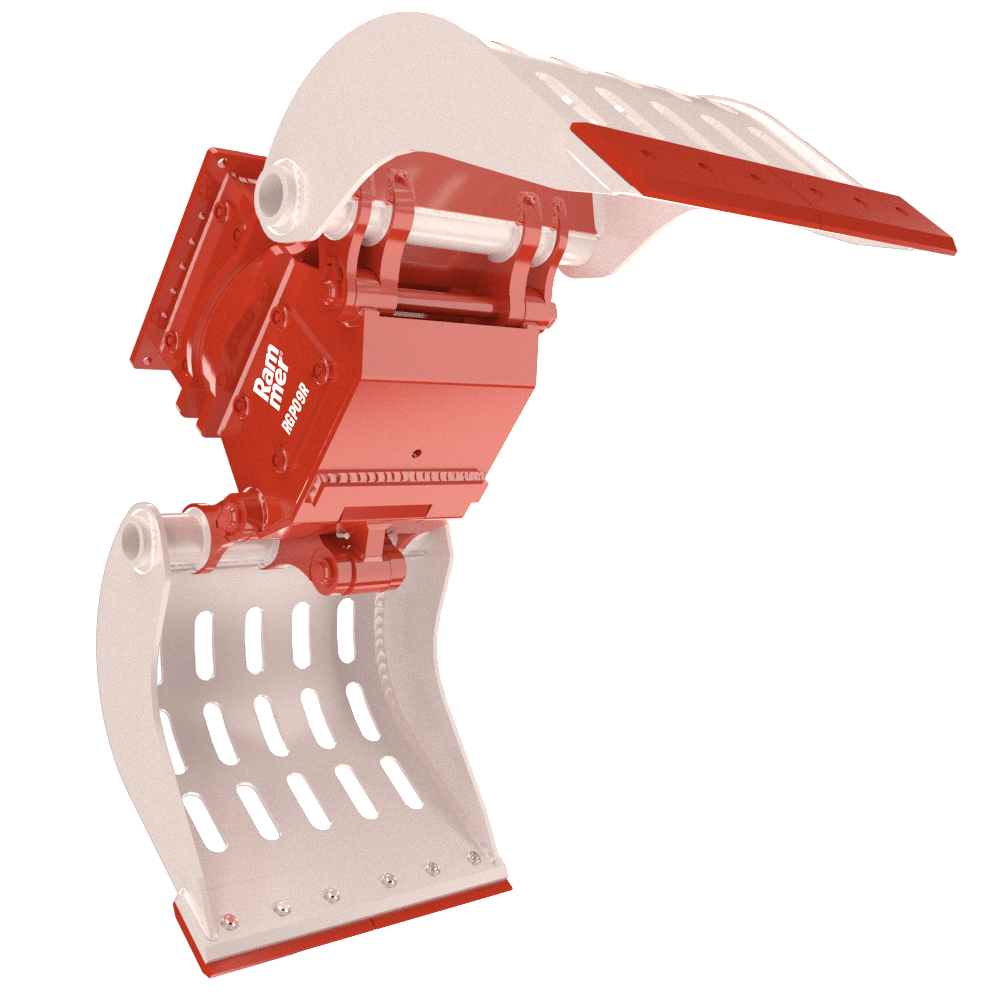

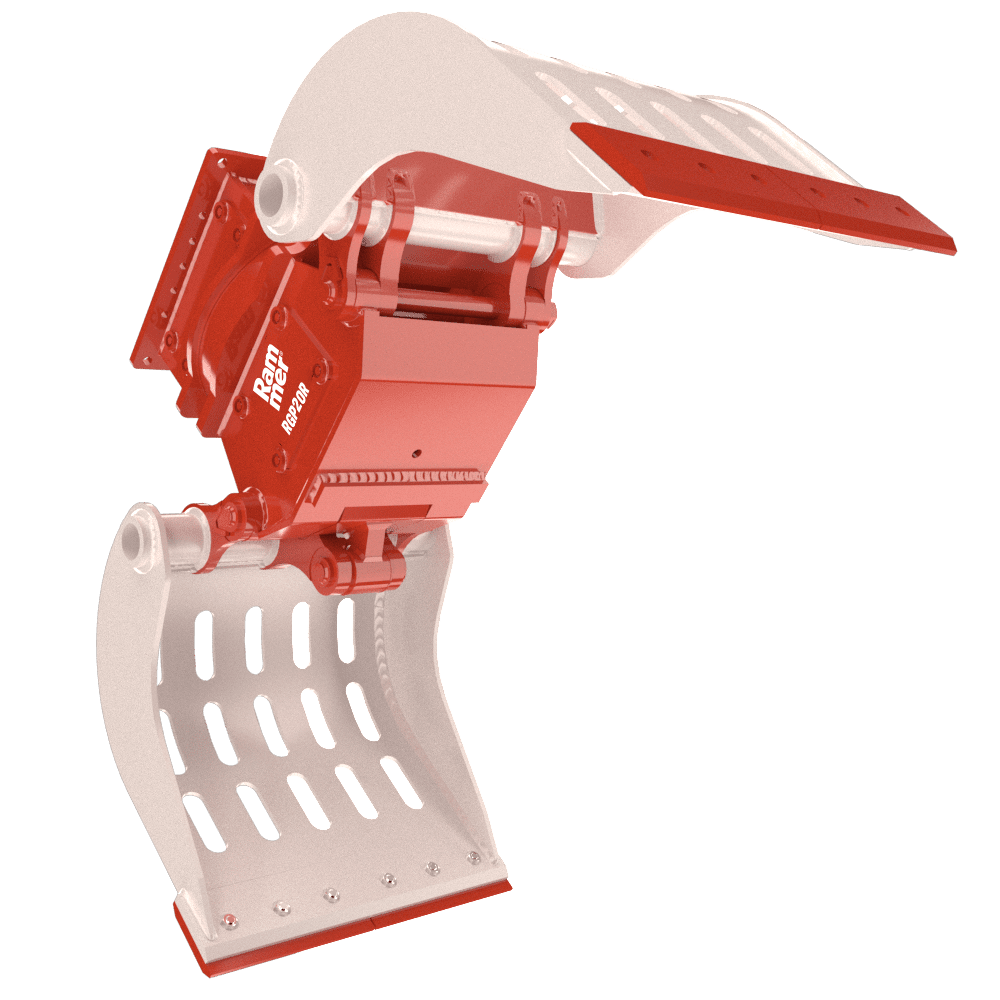

NO ROOM FOR PLAY

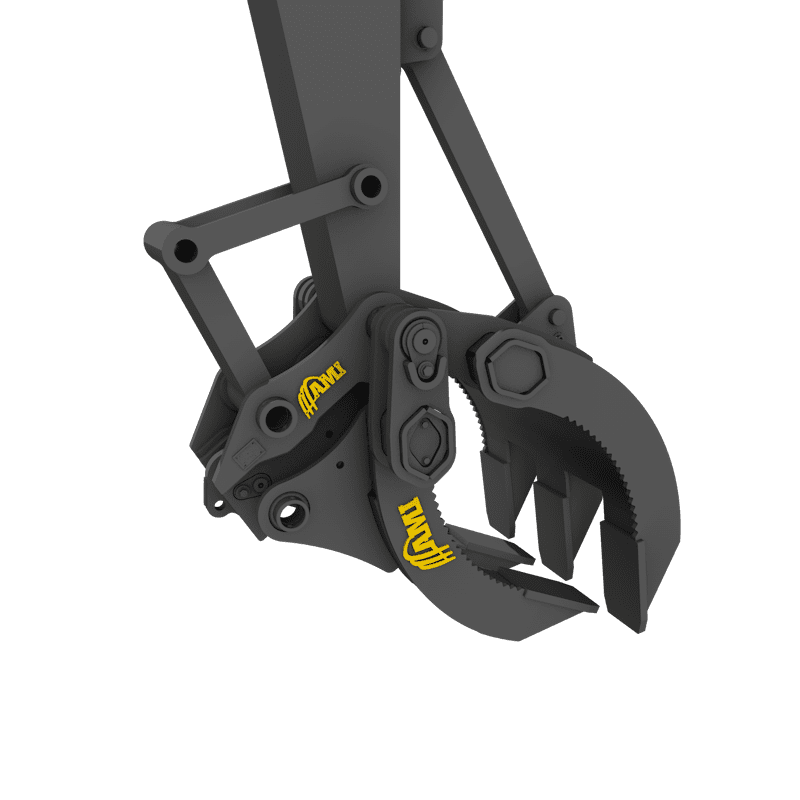

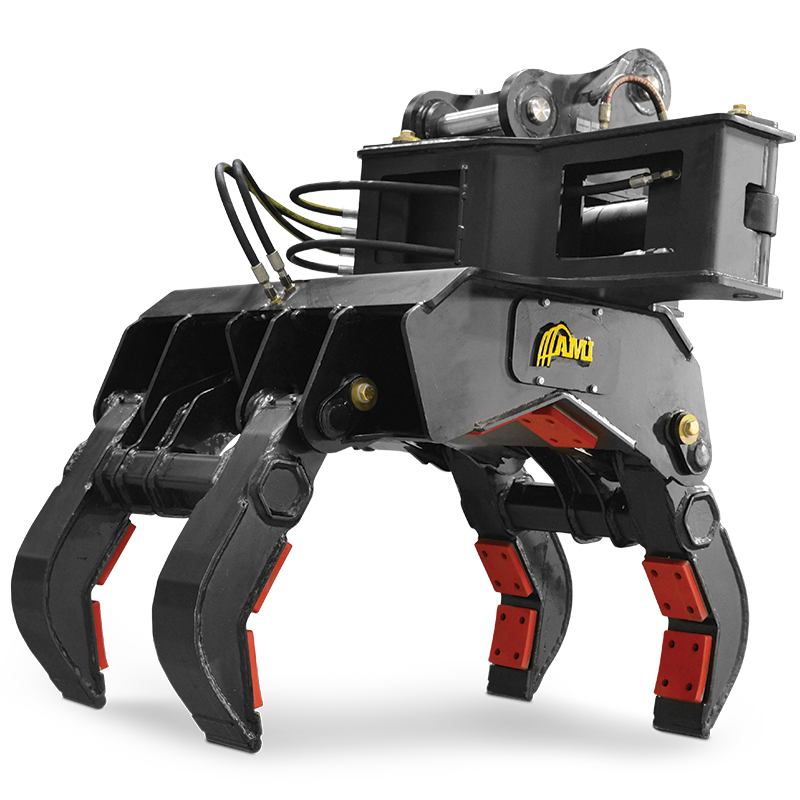

As you’d expect from a Hultdins grapple, the SuperGrip II features expander pins with an internal expander taper as standard. The pin diameter of the SuperGrip II is of course larger than that of much of the competition. This means that the force is spread over a larger area, resulting in a considerably longer service life.

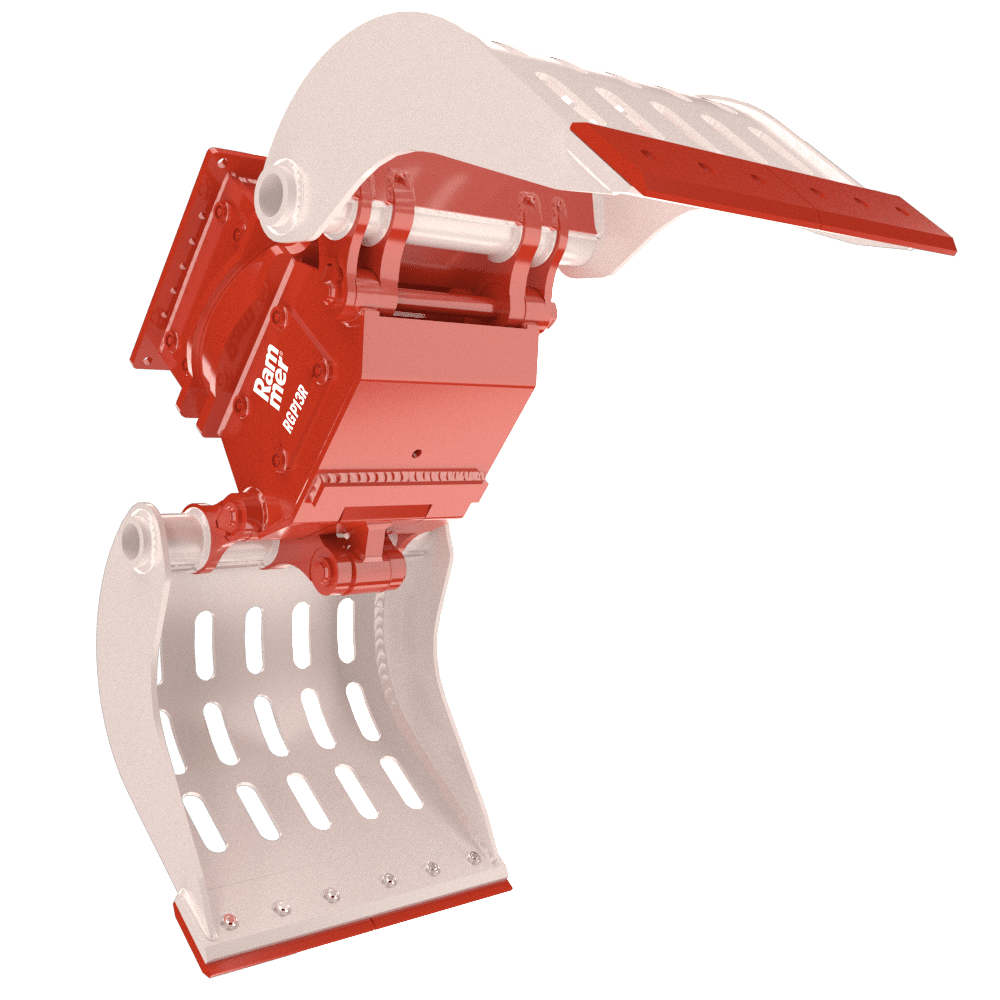

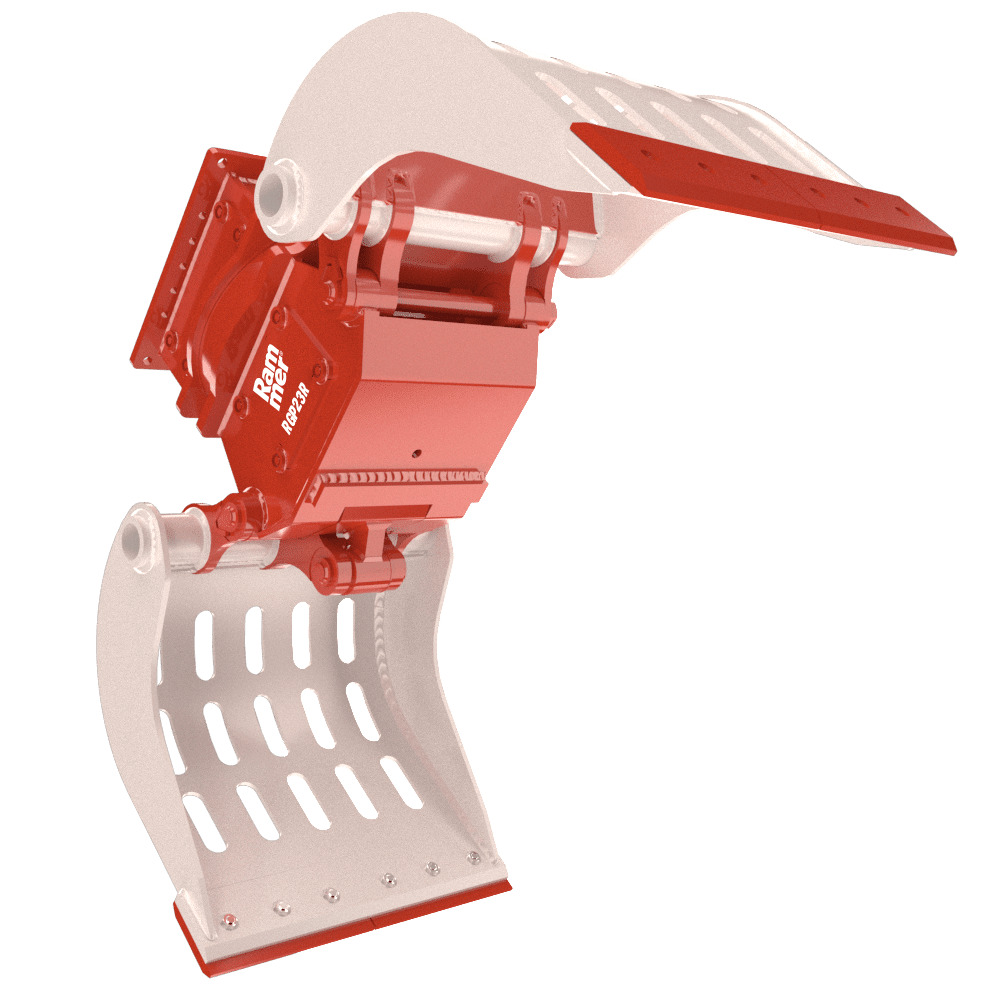

SOLID CAST METAL BRACES

The SuperGrip II std has only one brace, but it is solid cast metal. The powerful cylinder can handle up to 250 bar and is centered while the brace is placed to the side of the cylinder. The brace has a single purpose: to move the grapple arms in parallel without providing any additional force, ensuring that the force delivered to the grapple is evenly distributed. Since the external force on the plain bearing in a single brace is twice what it would be with double braces (compare with the SuperGrip), we’ve chosen robust steel bushings for the SuperGrip II.

Call Van-Ed

Call Van-Ed