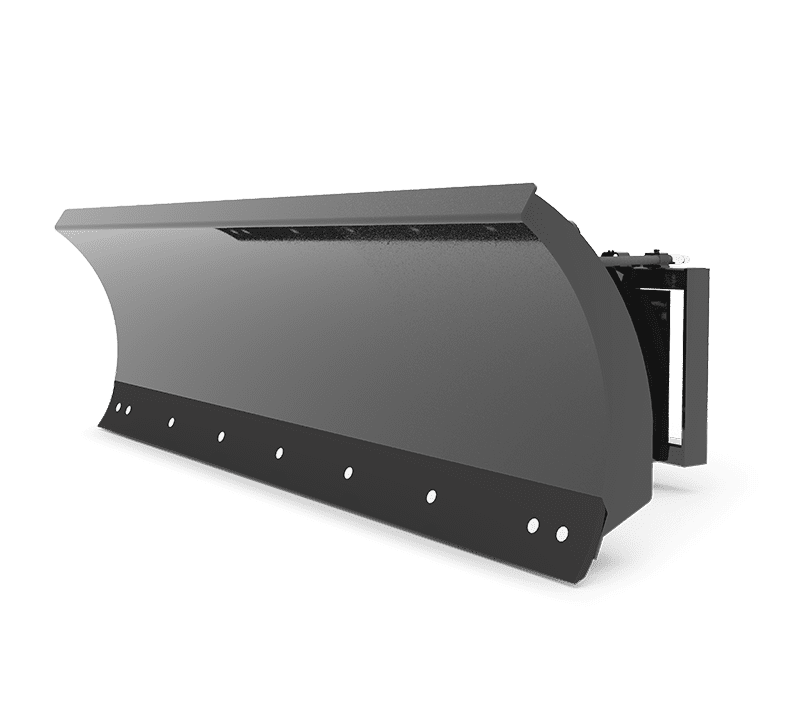

Product Overview

Max Operating Weight: 15,000 lbs

Taking full advantage of the HLA SnowPusher has never been easier. Ruggedly built with a welded double sidewall, the SnowPusher doesn’t need any bulky braces, ensuring smooth and clean lines inside. Finally, use the optional back drag or 3PH rear pull mount to pull snow away from tough to reach spaces, ensuring the lot looks the best it can.

- 2 Year Warranty – Designed for harsh conditions, HLA Snow backs its 3000, 4000, 5000, and 6000 series blades with a 2 Year Commercial Warranty.

- Replaceable, Reversible Cutting Edge – Our cutting edges are designed to be easily replaceable and are reversible to give you twice the life.

- Double Sidewall – Welded double sidewalls eliminates bulky braces and reduces material build-up, leaving only smooth clean lines inside.

- High Tensile AR400 Adjustable Steel Skidbars – AR400 high tensile skid shoes for optimum performance and prolonged cutting edge life.

- Spring Trip Cutting Edge – Allows cutting edge to trip back if struck by hidden object limiting damage.

- Carbide Cutting Edges – Carbide edges are designed for heavy commercial use. This non-reversible cutting edge is suited for heavy duty clearing on concrete or asphalt.

- Back Drag – Equipped with a steel edge on the back drag, this option is ideal for back dragging away from doors and loading docks for an even cleaner finish. Edges are drilled for either rubber or steel optional bolt-on cutting edges.

- 3PH Rear Pull Mount – Ideal for cleaning away from doors and loading docks, utilize your pusher as a pull unit.

- Lateral Float – Allows blade to follow ground contours for better clearing performance.

- Snowblade Marker – Add this to your blade for better visibility and blade position awareness.

- Poly Bolt-On Endplate Runner – Recommended for use with the rubber cutting edge option, helps prevent surface damage.

- Rubber Cutting Edge – The optional rubber cutting edge is available for select models. Standard on SP3500R models.

- Edge Flex Models – Available in Edge Flex. Segmented cutting edges available with standard hardox or heavy duty carbide.

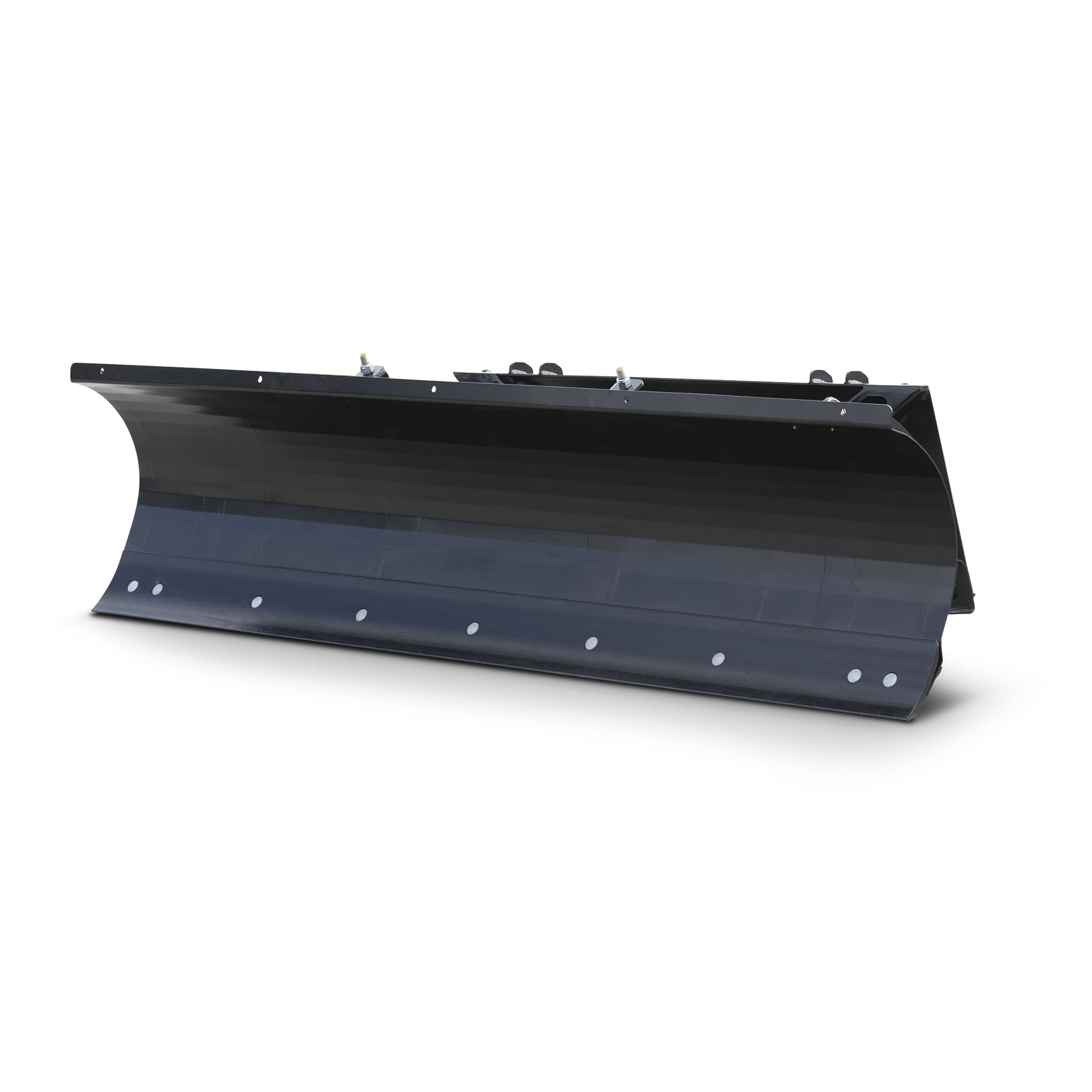

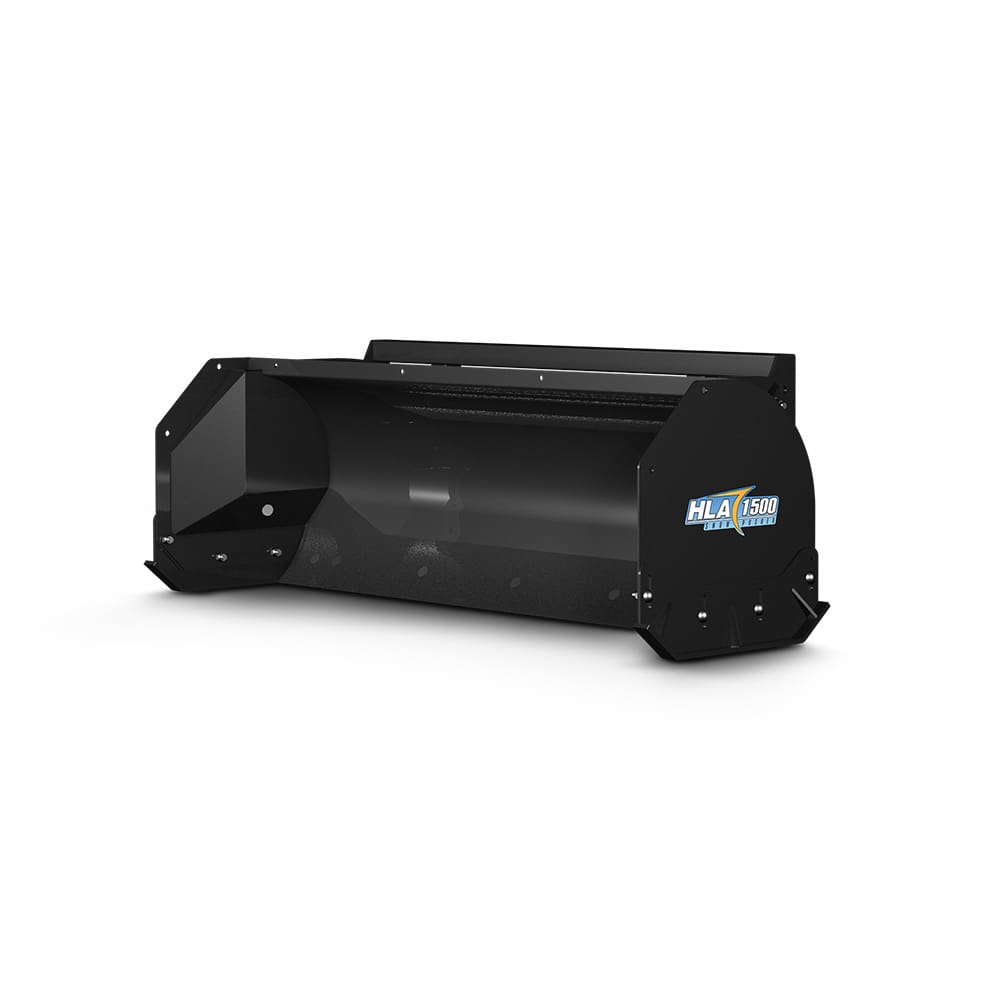

More products that you might be interested

More of

Got a question?

We’re here to help you pick out the best tool that suits your unique needs.

CONTACT US

Call Van-Ed

Call Van-Ed